Shanghai ZhongRui environmental protection equipment Co., Ltd. is a

new energy enterprise specialized in R&D, design, manufacture,

sales, and service, which engaged incomplete set of equipment for

crushing and sieving in mines, sludge treatment water recycling

system, and other environmental protection and energy-saving

products.

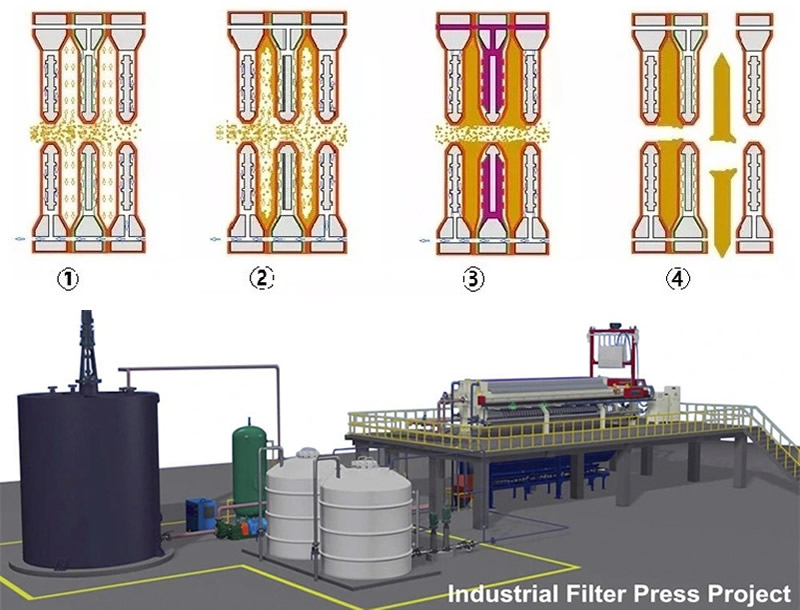

Self-developed products have reached the leading position in China,

features in high efficiency, low carbon, environmental protection,

and no pollution; such as single cylinder hydraulic cone crusher,

ultrafine energy saving crusher, hydraulic plate-frame filter

press, belt pressure filter, etc.

Products always pursue "high efficiency, energy-saving,

environmental protection" and the design concept is advanced.

Marketing tenet: do our best to give attentive service. Provide

cost-effective products and targeted solutions according to the

actual characteristics of the user.

Our company always adheres to the business strategy of "saving

enterprise costs, developing circular economy and sharing low

carbon life", promote the domestic and foreign markets, and

tailor-made different types of energy-saving and environmental

protection products for the enterprises in need. We are a faithful

partner for energy conservation development.